We just got back from London, where we helped our friends at [OpenCell] (http://opencell.webflow.io/) furnish their first container lab.

How did this happen? Well, about a month ago we were contacted by Helene Steiner, who, together with Thomas Meany, is in the process of setting up a container village for small biotech startups in the heart of London. The idea is to provide a professional workspace (10 biolabs, 20 offices, 10 studios for artists and designers, 4 workshop containers, 1 store) to small businesses and startups. She said to us “Hey guys, I saw you are interested in building container labs, we have 10 of them. Do you want to design the interior & layout for the first one and help us build it?”. Of course we agreed, as this would give us a change to design and test a first prototype of our lab workbench as well as try out different layouts for the container lab. The main challenge here is to fit all the necessary equipment into a small space and still create a nice work environment.

We came together for two weekend workshops and several evening-filling Skype-calls in which we discussed, refined and re-arranged workbenches, appliances and shelving. The space is approximately 12 x 2.2 m in size and needs to accommodate a sink, -80°C freezer, -20°C freezer, fridge, chemical fume hood, BSL2 cell culture hood, CO2 incubator, autoclave as well as space for four people to work and move around.

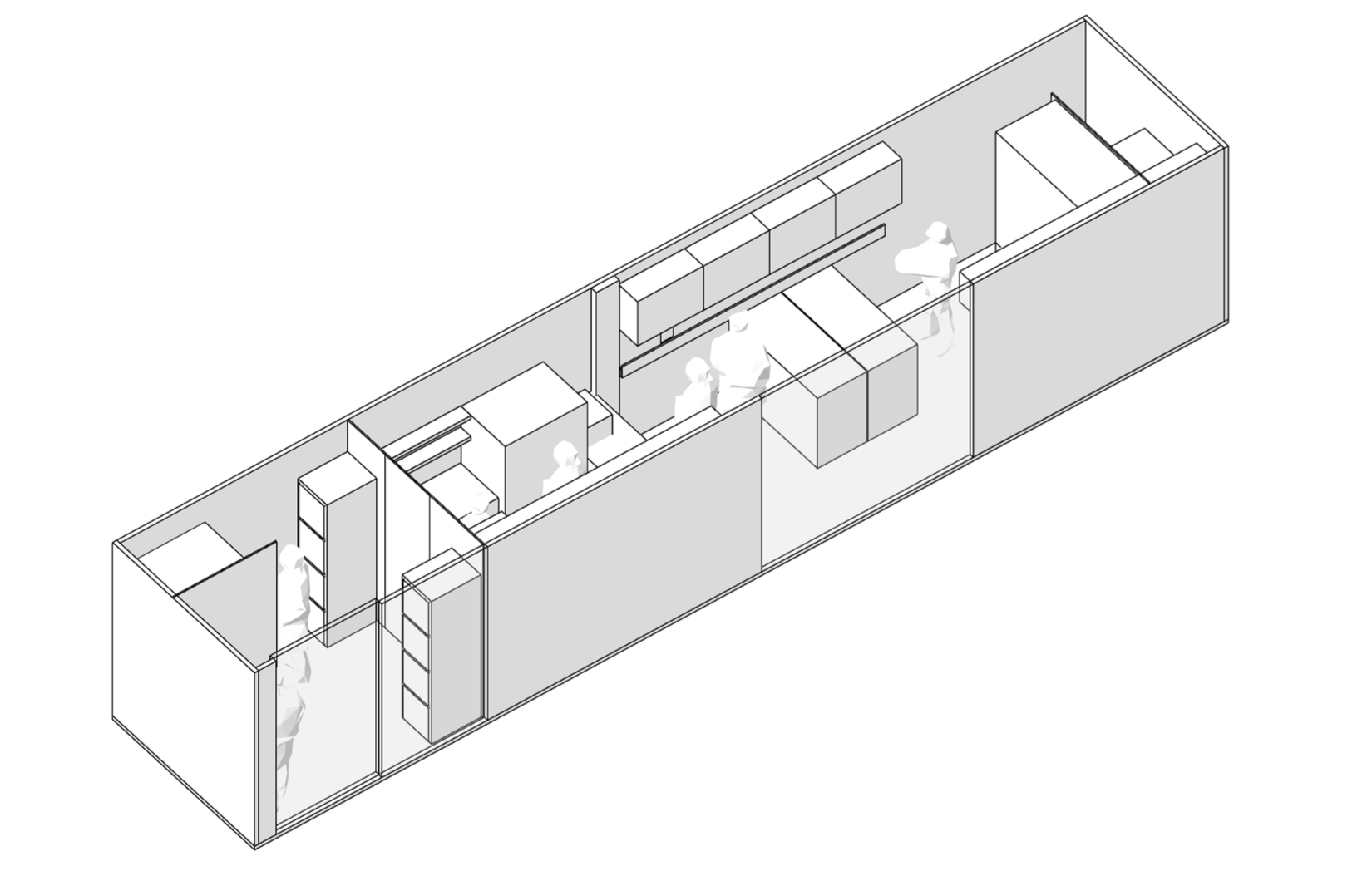

Here is what we came up with:

You enter the lab through the door on the left of the drawing, and find yourself in an ante-room separated from the rest of the lab by a sliding door. There is storage space for personal items, places to hang lab coats, and the -80°C freezer, which is used for low-temperature storage of samples. You enter the lab through the sliding door and have the sink on the left (for hand washing upon entering and leaving the lab) and the CO2 incubator and -20°C freezer and fridge on the right. Next to the sink is the chemical fume hood and a heavy-duty workbench. Then there are two back-to-back benches with storage shelves for bulk storage of non-heavy items (e.g. lab plasticware) above them. The benches are not facing the wall so as to avoid having to work with your back facing the large window. The door facing the workbenches is permanently locked and effectively serves as a window/emergency exit. At the far end of the lab is the BSL2 cabinet, which generates an air flow to keep the work surface and samples inside it sterile. Air movement (opening doors, people passing by) can interfere with air-flow and cause contamination, hence we placed the BSL2 cabinet in an area without much traffic and as far away from the door as possible. Behind the cabinet sits the large autoclave, which will be used for decontamination of waste at the end of the workday.

We had a plan.

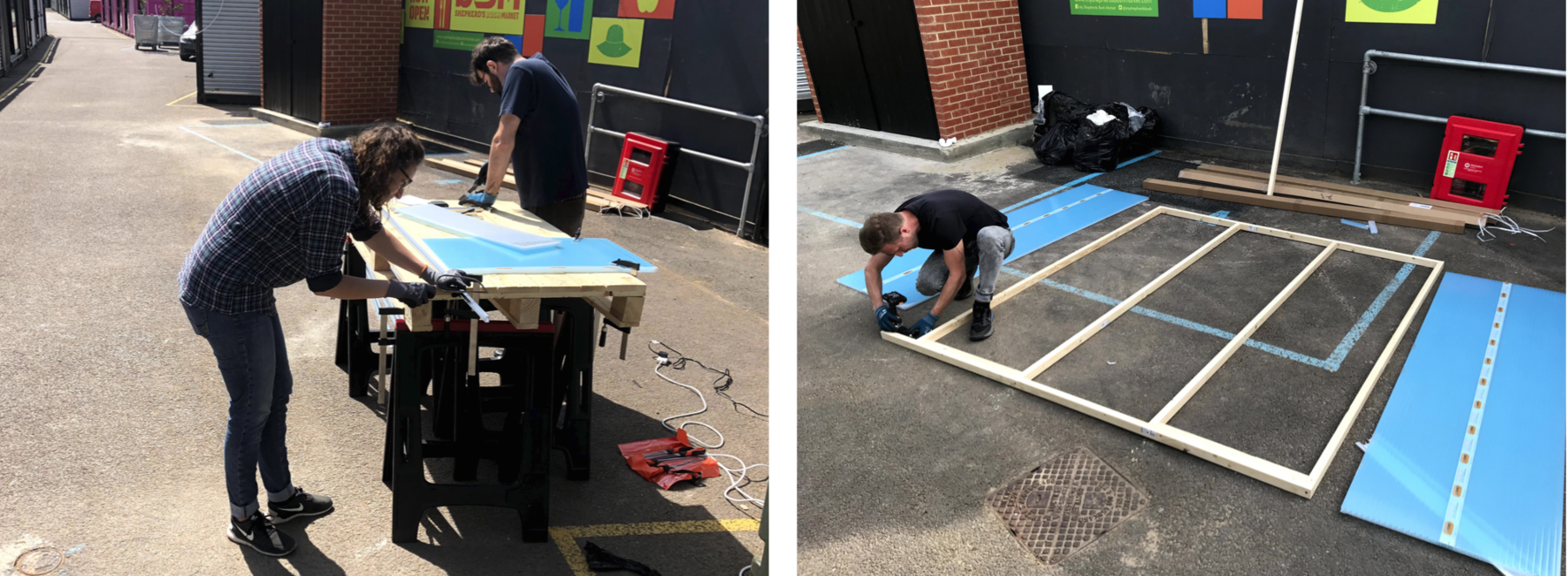

On 16th May we flew to London to build the lab, with a showcase to the public scheduled for the evening of 21st May. We thus had just 5 days to complete the lab. This is what the inside of the container looked like when we arrived:

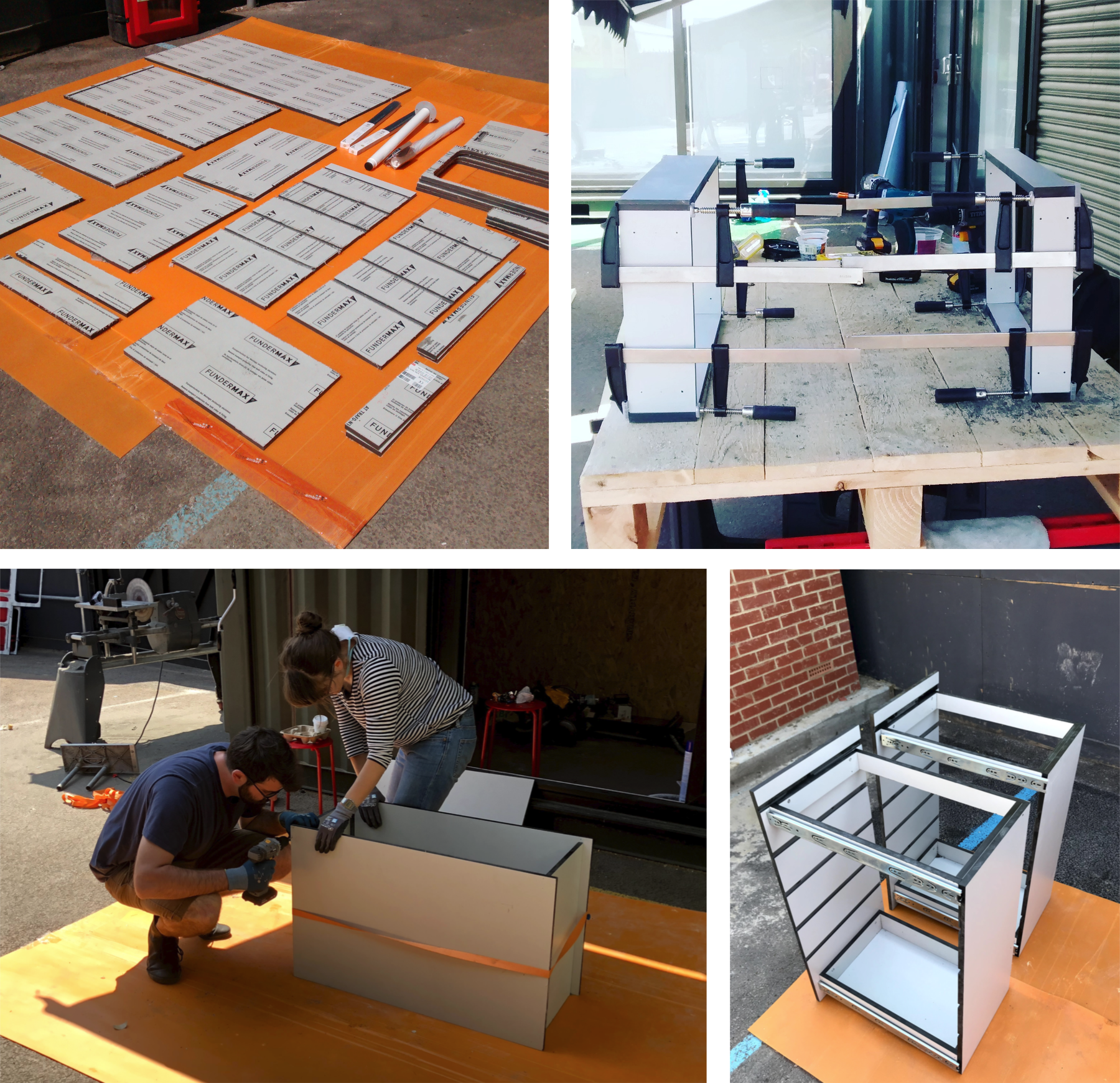

So we got down to work:

Here is the finished lab bench prototype. So proud.

In the evening of the 21st, people arrived for a short talk and tour around the lab. We presented Biotop, talked about our mission, past projects and how we became interested in container labs. We also explained the considerations affecting the lab layout.

Photos: Ralf Bliem, Anna Ritscher, Lukas Hutter, Anna Köferle, Andreas Körner

Rhys Votano and Jan Stöckel followed us around with their cameras during those 5 exciting days. They interviewed us about our backgrounds and how the Biotop X OpenCell project came into being. Watch the result here:

Video: Rhys Votano, Jan Stöckel